Well, I'll try and explain some of the steps involved:

|

|

Lamination of glass sheets

|

First a drawing or planning is made in the form of a design. Flat glass sheets are then cut to the approximate sizes (According to the measurements of the design, and leaving some "meat" for grinding). Then the sheets are laminated together using a UV-bonding adhesive.

|

|

Ground down to shape and size

|

After the lamination process the rough glass gets ground down to the desired shape and size.

|

|

Surface cut and colour added

|

Yes, this is still the same piece. Various layers of thin glass were laminated to the back using coloured UV-glue. Isnít it amazing how the glass absorbs the colour? The rough ground surface is then also cut on a sand stone wheel, smoothing the glass surface for polishing. (The glass is still wet on this image, giving the illusion of it being polished.)

|

|

Polished and shiny

|

Here we have the glass all polished up!

This is firstly done on poplar wood disk. A polishing medium gets applied to the disk with water. After the pre-polish we take the glass to a high-gloss polishing disk made of felt and the polishing medium gets applied once again with water. Mechanical polishing usually consists of two to three steps.

|

|

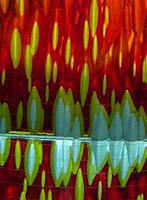

Is it burning?

|

For the final touch, cuts were made into the thinly laminated back, revealing the different layers of colour and giving the illusion of fire. The production of the glass is now finished and ready to be assembled into the sculpture.

|

|

Detailed close-up

|

On this close-up shot you can see some of the detail.

|